Wattlab is a Netherlands-based company that delivers solar power solutions for the shipping industry. HGK Shipping is a European inland waterway shipping company that operates a fleet of 350 vessels.

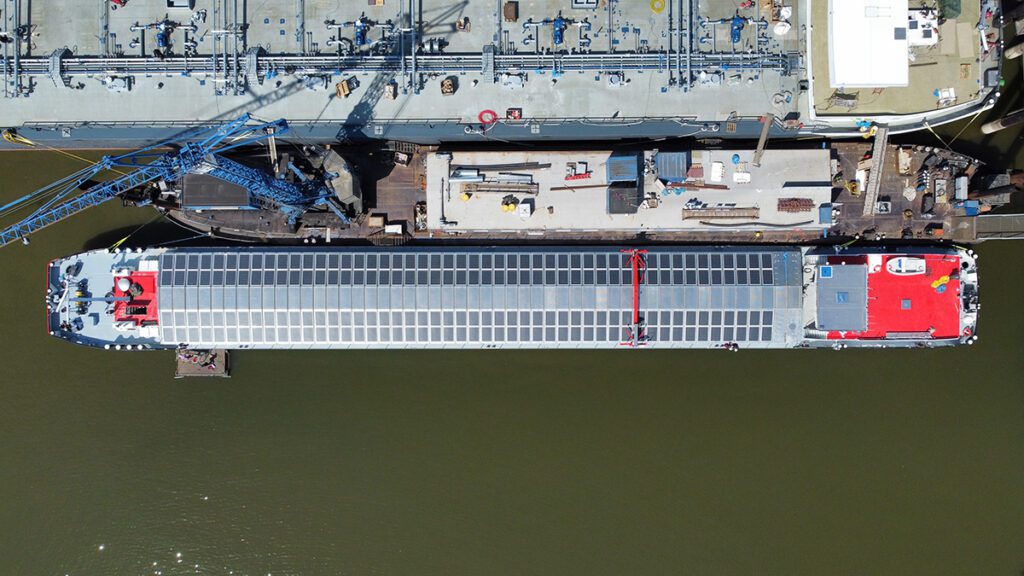

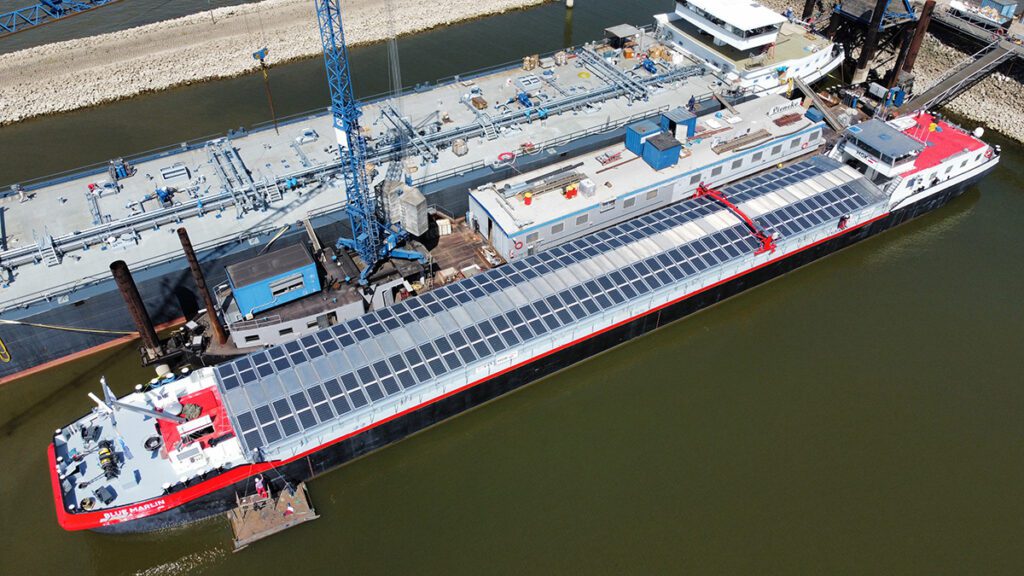

Now Wattlab has delivered a solar energy system for HGK Shipping’s inland cargo vessel the Blue Marlin. The vessel’s 192 solar panels will provide power to both the onboard and propulsion systems.

In 2024, Wattlab delivered a dry cargo vessel to HGK Shipping called MS Helios, which was equipped with 312 solar panels. This ship was actually recognized by Guinness World Records for having the world’s largest solar panel installation on an inland shipping vessel.

The solar energy systems of the Helios and the Blue Marlin differ in one major respect. The Helios used solar energy exclusively for low-voltage onboard (hotel) systems, but the Blue Marlin features a more advanced integrated system that’s capable of contributing power directly to the ship’s propulsion system.

“The Blue Marlin’s 192 solar panels are not only connected to the low-voltage onboard systems but also to the high-voltage propulsion network,” said Wattlab co-founder and COO David Kester. “This means that HGK Shipping can proudly state that they are the first inland shipping company to operate a vessel that uses solar power directly for propulsion.”

Delivering up to 35 kilowatts under optimal conditions, the Blue Marlin’s solar power system will operate in conjunction with four diesel generators. This setup enables peak shaving—this is a familiar concept for buildings, but onboard a ship it means that the combination of solar energy and batteries can eliminate the need to activate an additional generator during high-demand periods. The system’s automated energy management will distribute energy where and when it is required, increasing efficiency and reducing fuel consumption.

“In situations where the ship is lightly loaded and travelling downstream, we anticipate that it may even sail using only solar power for limited periods—an unprecedented achievement in the inland shipping sector,” says Kester.

Installation of the Blue Marlin’s solar panels took place at De Gerlien van Tiem shipyard, where Wattlab cooperated with Blommaert Aluminium and Van Tiem Electro. “We have been working with these partners for some time now, so have managed to really optimize the processes, said Kester. “The Blue Marlin is a new-build vessel—it took about one week for installation, followed by a few days for commissioning. Considering a similar-sized retrofit project, we estimate that a shipowner would be looking at a downtime of no more than one week.”

Source: Wattlab